Latest on semiconductor supply news: what you need to know

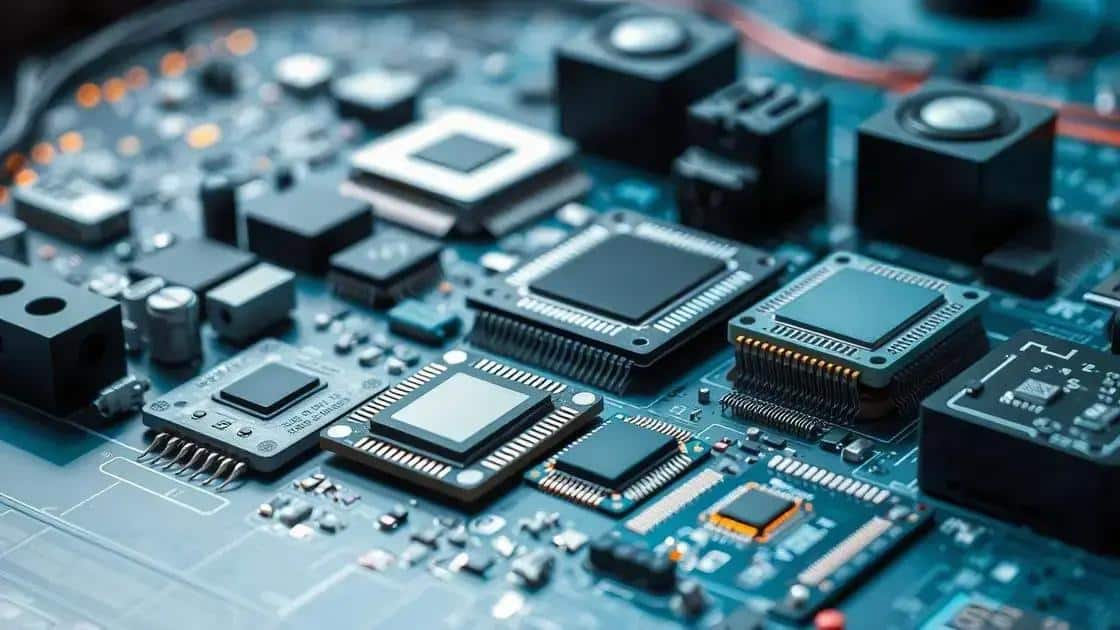

The latest on semiconductor supply news highlights critical factors such as global shortages, increased demand in various industries, and the shift towards local manufacturing and sustainability practices to enhance supply chain resilience.

Latest on semiconductor supply news reveals essential insights about the evolving market dynamics. With global demand surging, understanding these developments can greatly influence your decisions and strategies in technology sectors.

Overview of the current semiconductor supply chain

Understanding the current semiconductor supply chain is essential for grasping how the tech industry operates today. With advancements in technology, the demand for semiconductors has surged, resulting in a complex web of suppliers and manufacturers.

Key components of the supply chain

There are several crucial elements that contribute to the semiconductor supply chain:

- Raw Materials: Essential materials include silicon, which is the foundation of most chips.

- Manufacturing: This is where design and fabrication come together to create semiconductors.

- Assembly and Testing: After manufacturing, semiconductors undergo thorough testing to ensure functionality.

- Distribution: Finished products are shipped to various tech companies for use in electronic devices.

The flow of these components is affected by various factors, including global trade policies and technological advancements. Supply disruptions can occur due to political tensions or natural disasters, impacting availability. Understanding these dynamics is crucial for companies relying on semiconductors.

The role of major players

Several major players are reshaping the landscape of the semiconductor supply chain. For example, companies like TSMC and Intel are at the forefront of semiconductor manufacturing, pushing boundaries in design and efficiency. Their innovations drive the entire industry forward, influencing supply and demand trends.

Moreover, the rise of electric vehicles and IoT devices creates increasingly complex demands for specific chips, showing how interlinked industries impact the semiconductor world. As technology evolves, so does the semiconductor supply chain, adapting to meet new challenges.

Key factors affecting semiconductor availability

Several key factors significantly affect the availability of semiconductors today. Understanding these factors helps businesses navigate the rapidly changing landscape.

Global Supply Chain Issues

The semiconductor industry relies on a complex global supply chain. Any disruptions in this chain can severely impact production. For instance, logistic challenges due to shipping delays or port congestion can hinder the delivery of essential materials.

- Shipping Delays: Increased shipping times can lead to shortages.

- Climate Events: Natural disasters can damage facilities and disrupt operations.

- Political Tensions: Trade conflicts and tariffs can complicate sourcing.

In addition, the ongoing effects of the pandemic have exacerbated these issues. With factories temporarily closing or reducing capacity, companies have struggled to keep up with demand.

Technological Advancements

Emerging technologies, such as 5G and artificial intelligence, are driving higher demand for specialized chips. This demand puts pressure on manufacturers to adapt quickly. New trends can lead to unexpected shortages in production capabilities.

The fast-paced evolution of technology means older semiconductor designs may become obsolete, requiring companies to invest in research and development. This pressure to innovate can strain resources and affect supply availability.

Additionally, the demand for electric vehicles (EVs) has significantly increased recently. EVs require unique semiconductors that differ from traditional vehicles, which further complicates the supply chain. Understanding these dynamics is vital for companies looking to thrive in today’s market.

Impact of semiconductor shortages on various industries

The impact of semiconductor shortages is felt across multiple industries, reshaping how companies operate and affecting consumers directly. As demand for technology increases, many sectors struggle to find essential components.

Automotive Industry Challenges

The automotive industry has been notably hit hard by semiconductor shortages. Newer vehicles often rely on a wide range of chips for functions such as navigation, safety features, and entertainment systems. With limited supply, automakers face production delays.

- Production Cuts: Many manufacturers have had to halt or slow down production.

- Rising Costs: As a result of shortages, the prices of vehicles are skyrocketing.

- Increased Lead Times: Customers now experience longer waiting periods for their cars.

This has forced companies to prioritize chip allocation, which can shift based on immediate needs and production cycles.

Electronics and Consumer Goods Impact

The electronics sector also experiences significant disruptions. The demand for consumer electronics, like smartphones and laptops, surged during the pandemic, which can worsen supply issues.

Manufacturers are facing tough choices regarding resource allocation. With higher demand than supply, popular products may become scarce. This affects everything from production timelines to consumer pricing.

Furthermore, manufacturers in the TV and home appliance markets see difficulties due to a lack of availability of critical components. The ripple effect of these shortages can slow down innovation and development across the industry.

In summary, semiconductor shortages are reshaping the landscape for multiple industries, leading to production delays, rising costs, and an overall challenge in meeting consumer demand.

Future trends in semiconductor supply

Understanding the future trends in semiconductor supply is crucial for businesses and consumers alike. With technology evolving rapidly, several trends are shaping the way semiconductors are produced and distributed.

Increased Demand for Specialty Chips

The need for specialty chips will rise in various sectors, including automotive, healthcare, and consumer electronics. For instance, as the demand for electric vehicles grows, manufacturers will require specific semiconductors that control battery management and electric drivetrains.

- Growth in IoT Devices: More connected devices will need specialized chips.

- AI and Machine Learning: These technologies demand powerful processing units.

- Healthcare Innovations: Medical devices require reliable and advanced semiconductor solutions.

This shift will likely lead to an increase in R&D activities to develop innovative chips tailored for specific applications.

Investment in Domestic Manufacturing

Countries are beginning to focus more on local semiconductor manufacturing as a way to reduce dependency on foreign suppliers. This trend has grown due to recent supply chain disruptions.

Increased investment in domestic facilities will help build a more resilient supply chain. Governments are providing incentives to encourage companies to establish production plants locally, which can help meet demand and boost the economy.

Furthermore, as companies focus on sustainability, there is a growing emphasis on producing semiconductors in environmentally friendly ways. This includes using renewable energy sources and reducing waste during the manufacturing process.

Overall, the future of semiconductor supply is evolving with new demands and innovative solutions, adapting to the needs of increasingly technological societies.

FAQ – Frequently Asked Questions about Semiconductor Supply

What are the main factors affecting semiconductor availability?

Key factors include global supply chain issues, increased demand for specific types of chips, and production capacity constraints due to recent disruptions.

How do semiconductor shortages impact the automotive industry?

Semiconductor shortages lead to production delays, increased costs for vehicles, and longer wait times for consumers.

What trends are shaping the future of semiconductor supply?

Future trends include a rise in demand for specialty chips, increased local manufacturing investments, and a focus on eco-friendly production methods.

Why is sustainability important in semiconductor manufacturing?

Sustainability is important to minimize environmental impact, reduce waste, and meet the growing consumer demand for environmentally responsible products.